What are the popular braking resistor product models?

Popular Braking Resistor Product Models

I. Introduction

Braking resistors are essential components in various electrical and mechanical systems, primarily used to dissipate energy during braking. They play a crucial role in ensuring the safety and efficiency of applications ranging from industrial machinery to electric vehicles. This article aims to provide an overview of popular braking resistor product models, their features, and considerations for selecting the right model for specific applications.

II. Understanding Braking Resistors

A. Function and Operation of Braking Resistors

Braking resistors serve to dissipate excess energy generated during braking. When a motor is decelerated, it can act as a generator, converting kinetic energy back into electrical energy. This energy must be managed effectively to prevent damage to the system. Braking resistors absorb this energy, converting it into heat, which is then dissipated into the environment.

1. Energy Dissipation During Braking

The primary function of braking resistors is to convert the electrical energy produced during braking into thermal energy. This process helps to prevent voltage spikes that could damage the motor or drive system.

2. Role in Regenerative Braking Systems

In regenerative braking systems, braking resistors are crucial for managing the energy that is fed back into the power supply. They ensure that the energy is safely dissipated when it cannot be reused, thus enhancing the overall efficiency of the system.

B. Types of Braking Resistors

Braking resistors can be categorized into several types based on their application and functionality:

1. Dynamic Braking Resistors

Dynamic braking resistors are used in applications where rapid deceleration is required. They are typically employed in electric drives and cranes, where quick stopping is essential.

2. Regenerative Braking Resistors

These resistors are designed to work with regenerative braking systems, allowing for the recovery of energy that can be reused in the system, thus improving energy efficiency.

3. Mechanical Braking Systems

In some cases, mechanical braking systems may also incorporate resistors to enhance performance and safety, particularly in heavy machinery.

III. Key Features of Braking Resistors

When selecting a braking resistor, several key features should be considered:

A. Power Rating and Capacity

The power rating indicates the maximum amount of energy the resistor can handle without overheating. It is essential to choose a resistor with an appropriate power rating for the specific application.

B. Thermal Management

Effective thermal management is crucial for the longevity and performance of braking resistors. Features such as heat sinks or cooling fans can enhance thermal dissipation.

C. Resistance Value and Tolerance

The resistance value determines how much energy the resistor can absorb. Tolerance levels indicate how much the actual resistance may vary from the specified value, which can impact performance.

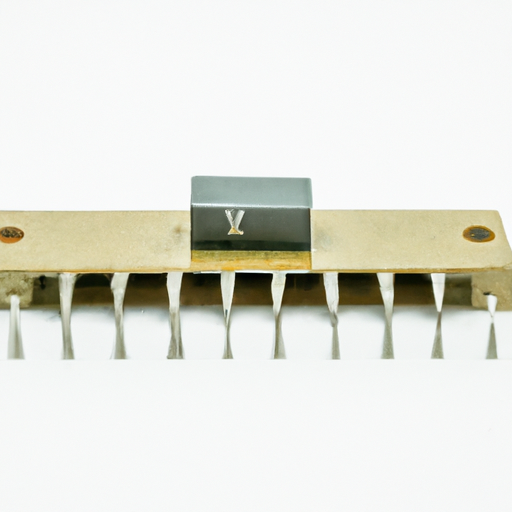

D. Construction Materials and Design

Braking resistors are typically made from materials that can withstand high temperatures and resist corrosion. The design can also affect the resistor's performance and durability.

E. Mounting Options and Configurations

Braking resistors come in various mounting options, including panel-mounted, chassis-mounted, and standalone configurations. The choice depends on the specific installation requirements.

IV. Popular Braking Resistor Product Models

A. Overview of Leading Manufacturers

Several manufacturers are recognized for their high-quality braking resistors. Some of the leading brands include:

1. **Siemens**

2. **ABB**

3. **Schneider Electric**

4. **Eaton**

5. **Allen-Bradley**

B. Detailed Examination of Popular Models

1. Siemens 6RA80 Series

Specifications: The Siemens 6RA80 series offers a range of braking resistors with power ratings from 10 kW to 100 kW. They are designed for dynamic braking applications and feature robust thermal management systems.

Applications: Commonly used in cranes, elevators, and other industrial machinery requiring rapid deceleration.

2. ABB DCS800 Series

Specifications: The ABB DCS800 series includes braking resistors with power ratings up to 200 kW. They are designed for use in regenerative braking systems and feature advanced thermal management.

Applications: Ideal for applications in the marine, mining, and metals industries.

3. Schneider Electric Altivar Series

Specifications: Schneider Electric's Altivar series offers braking resistors with customizable power ratings and resistance values. They are designed for both dynamic and regenerative braking applications.

Applications: Widely used in HVAC systems, conveyors, and other industrial automation applications.

4. Eaton PowerXL Series

Specifications: The Eaton PowerXL series features braking resistors with power ratings ranging from 5 kW to 150 kW. They are designed for high-performance applications and include advanced thermal management features.

Applications: Suitable for use in material handling, packaging, and process automation.

5. Allen-Bradley Kinetix Series

Specifications: The Allen-Bradley Kinetix series includes braking resistors with power ratings from 10 kW to 100 kW. They are designed for use in servo and motion control applications.

Applications: Commonly used in robotics, CNC machines, and other precision motion control systems.

V. Comparison of Popular Models

A. Performance Metrics

When comparing braking resistor models, performance metrics such as power rating, thermal management efficiency, and resistance value are critical. Each model has unique strengths that cater to different applications.

B. Cost Considerations

Cost is an important factor when selecting a braking resistor. While high-quality models may come with a higher price tag, they often provide better performance and longevity, making them a worthwhile investment.

C. Application Suitability

Different models are suited for specific applications. Understanding the requirements of your application will help in selecting the most appropriate braking resistor.

D. User Reviews and Feedback

User reviews can provide valuable insights into the performance and reliability of braking resistor models. Researching feedback from other users can help inform your decision.

VI. Factors to Consider When Choosing a Braking Resistor

A. Application Requirements

Consider the specific requirements of your application, including power needs, braking frequency, and environmental conditions.

B. Environmental Conditions

Braking resistors must be able to operate effectively in the environmental conditions of their application, including temperature, humidity, and exposure to contaminants.

C. Compatibility with Existing Systems

Ensure that the braking resistor is compatible with your existing systems, including motors, drives, and control systems.

D. Budget Constraints

While it is essential to invest in a quality braking resistor, it is also important to consider your budget. Balance performance needs with cost to find the best option.

VII. Conclusion

Selecting the right braking resistor is crucial for ensuring the safety and efficiency of your applications. With various models available from leading manufacturers, it is essential to consider your specific needs and requirements. As technology continues to evolve, the future of braking resistor technology promises even greater efficiency and performance enhancements.

VIII. References

- Manufacturer websites and product catalogs

- Industry publications and technical papers

- User reviews and feedback platforms

In conclusion, understanding the various braking resistor models and their features can significantly impact the performance of your systems. By considering the factors outlined in this article, you can make an informed decision that meets your application’s needs.